Epoxy Floors

Epoxy Floors

Your garage is, well, a garage. It’s fine. Would you rather have a space that looks good, a space you want to use? Yes. That’s why TerraFirma has epoxy floors for you.

What are epoxy floors?

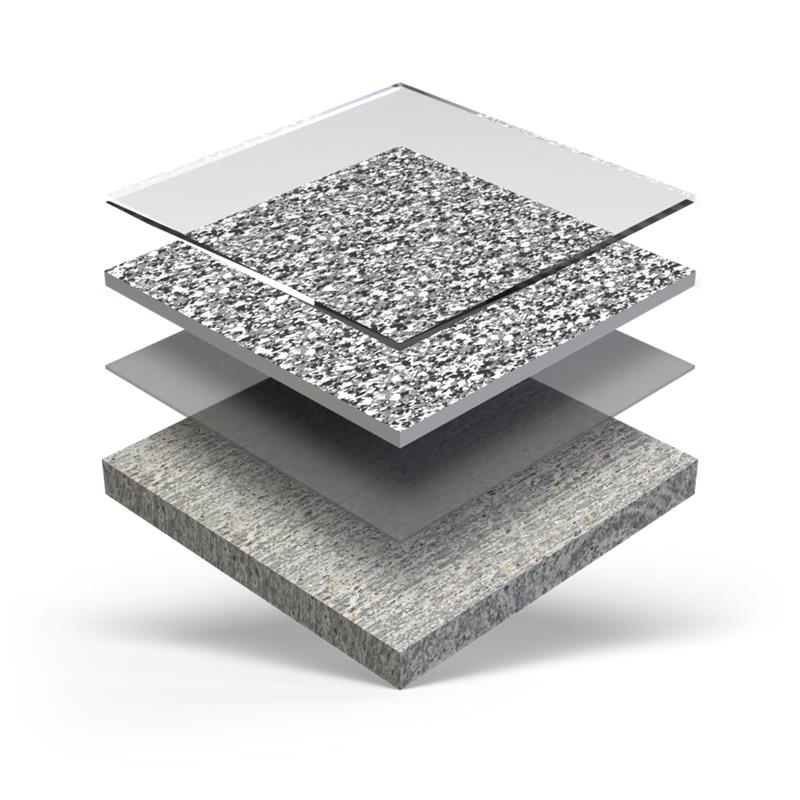

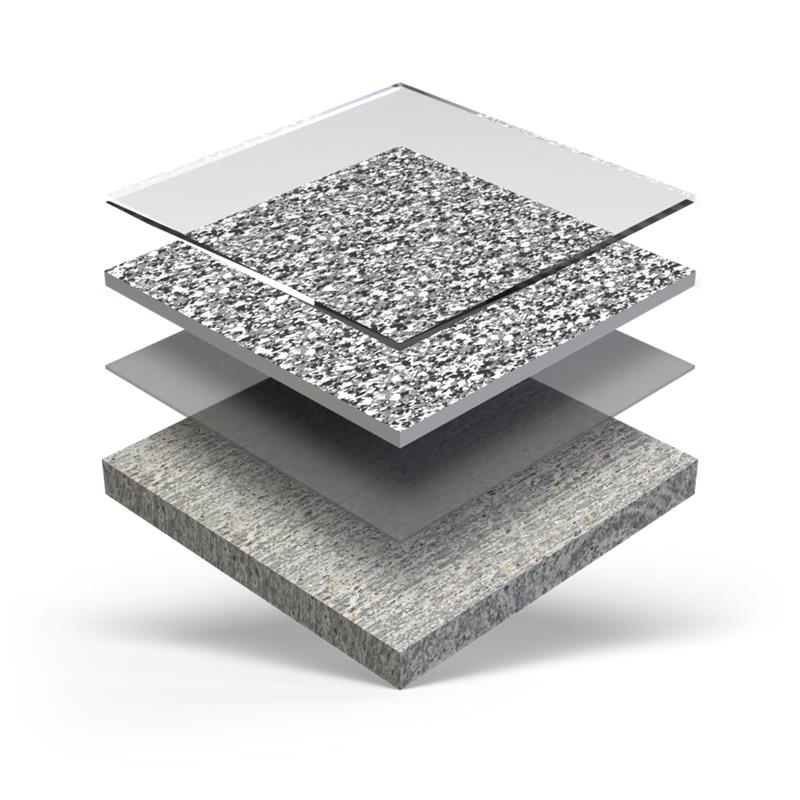

The Simple Answer: It’s a multi-layer system of durable material that is applied to your concrete floor. It also looks good.

The complex answer? Keep reading.

How do epoxy floors work?

Understanding the process of how we install epoxy floors will help you understand how they work. When we get to your home, we:

Prepare the Floor

We start by filling in chips, cracks, and removing anything that would prevent adhesion. This makes it a relatively level surface.

Grind It

We remove the top 1/16” of the concrete by grinding it down. This provides a great surface for our products to adhere to.

The Basecoat

We use a polyaspartic, a two-component, rapid-cure basecoat. It adheres well to the roughed-up concrete.

Broadcast Chips

We literally cast broadly, handfuls of the decorative vinyl chips till we’ve completely covered the floor. We do this while the basecoat is still tacky so the chips will adhere.

Scrape Excess

Then we scrape off the excess decorative flake. Sorry, we didn’t have a pic of this, but this is a nice closeup of the finished product.

Apply Finish

We use a polyaspartic, two-component, rapid-cure floor coating that seals the whole application and dries fast. It’s super durable, stain resistant, has a glossy sheen, and is perfect for indoor or covered spaces.

Epoxy Floor Prep

The main one we install uses vinyl paint chip flakes, and this is what they look like:

They look great. They have the advantage of being able to hide cracks, discoloration, etc. You’d have to look pretty close to see imperfections through floors we install. Even big cracks that we’ve filled can disappear into the random field of chips.

How long do they take to install?

It usually takes one day to install 400 square feet of epoxy flooring. At around 36 hours you can walk on the floor and it’s about four days till you can park your car on it.

Need an Epoxy Floor in your Garage?

Recommended uses for epoxy floors.

There are many places you could install epoxy floors:

- Garages

- Covered Patios

- Home Workshops

- Restaurants, Bars & Cafeterias

- Public Spaces in Stadiums & Malls

- Kennels & Labs

- Lobbies and Restrooms

- Any place you want a hard & tough floor.

Why get TerraFirma’s epoxy floors?

There are a lot of options for floor coatings. Some are cheap DIY projects from Home Depot that will last a year or two, but this isn’t just some paint and chips. TerraFirma provides high quality products & services and epoxy floors are no exception. We install a highly durable system you can feel confident in. Want to know even more? Keep reading below.

Everything about Epoxy Floors

The section above was mostly a summary, so lets get into the nitty-gritty of epoxy floors. We test-installed floors so we could get some good images as well as see the whole process. It’s pretty awesome.

Epoxy Floor Prep

This is a big part of the process and ensures we get good adhesion. Some of the factors are:

- Moisture – Water messes up the basecoat adhesion, so we check to see what moisture sources there are. Luckily, we are masters of water management under your home. TerraFirma can install any of our usual waterproofing/management services if there’s a problem. If that’s not enough we can apply an additional water-proofer under the basecoat for a bit more moisture control. The whole point is we want the basecoat to adhere, and moisture can interfere with that.

- Appliances/Objects – Yeah, you’re going to have to move all that stuff before we start. Things to be aware of:

- Water Heater: Sometimes they’re on a cement platform, but usually they’re on a metal table or sitting on the floor. If you want the epoxy flooring to go underneath, it will have to be moved. We don’t move them.

- Washer & Dryer: The garage is a good place to keep these. If you want the flooring to go under them, you will need to move them. We don’t move appliances.

- Shelving, Tools, etc.: If you want the epoxy flooring in a spot, it needs to be cleared of the things on that spot. We know this seems obvious, but it absolutely needs to be said. Our team is there to apply the flooring only.

- Lifting & Leveling – If the cement is uneven, we can use our Polylevel system to lift it and fill voids underneath the concrete. It’s not going to be perfectly level, concrete is usually pitched so water will run off in a specific direction, but we do want the joints and cracks to be evened out so there are no lips to trip on.

- Cracks – There are two main solutions we have for this:

- Hairline Cracks: We use an epoxy crack filler to fill these in. This is a two-component epoxy that can be used on vertical and horizontal surfaces.

- Large Cracks: We have a polyurea crack-filler that is a highly durable structural repair material and a good long-term fix. We can fill pretty large breaks in concrete with this stuff.

- Seams – When the cement slabs are poured, engineers include expansion gaps and seams. They allow for the slab to expand and handle a small amount of movement without cracking. We like to preserve these joints, so you will see the lines on the finished floor.

- Chips & Holes – That same polyurea crack-filler for large cracks can be used to fill in chips and holes in concrete. We can even use it to replace missing chunks in things like steps. It’s really ugly, but if we’re covering it with an epoxy floor it’ll look great. The best part is you’ll have un-chipped surfaces and straight lines on your steps again.

- Grinding – Once we’ve fixed all the problems with the floor we bring out the big grinder. It tears up the top concrete which provides the best surface for our basecoat. It removes about 1/16 of an inch, but the epoxy floor will more than make up for that. We use big vacuums with centrifuges and filters to make sure we don’t create a huge dust cloud

Epoxy Floor Basecoat

Now that the floor is prepped, we put down the basecoat. It’s a two-component polyaspartic basecoat. We mix the two parts which activate the chemical reactions that will adhere to the concrete as well as the decorative chips later. We cover the entire floor with the basecoat using large metal spatulas. The basecoat is rapid-cure so we don’t have to wait a hours or days before we continue to the next steps. It also has high solids and low odor along with excellent adhesion.

Epoxy Walls?

While we don’t do entire walls of epoxy flooring, we can go up the sidewalls a bit. Often garages will have the foundation stem-wall exposed between the drywall and floor. We can coat this for a nice, finished look. The surface will be rougher than the floor and we include the square footage in the cost.

Epoxy Floor Decorative Chips

This is the star of the show, the part you see. The chips are made from UV stable vinyl which means they are resistant to fading, discoloration, and degradation of the vinyl. It’s good quality stuff and we’re not stingy with it. We throw out enough to cover every inch of floor and then some. It’s about 80 pounds of chips per 400 square feet.

Waste Not

We scrape off the excess decorative flake after the bottom layer has adhered to the basecoat. The surface is not smooth and has some texture to it which will affect the topcoat.

Polyaspartic Coating

The final coating that seals it all is polyaspartic. It’s easy to clean, has a glossy finish, resists abrasion or scratches, has chemical resistance, high solids, low odor, and is LEED compliant. It takes 36 hours before you can walk on it and four before you can park your car on it. The surface, though glossy, will not be smooth because of the decorative chips.

This is where we have to say polyaspartic is not epoxy. Though polyaspartic and epoxy are both resin-based, polyaspartic is not the same thing as epoxy. It’s lumped in with epoxy and other products in the durable floor coating space. And since everyone searches for epoxy floors when looking for polyaspartic, we all call it epoxy.

Polyaspartic cures faster, is a little more UV resistant, and is more durable than epoxy. It’s a better product all the way around. It’s harder to handle and install so that’s why you want a professional like TerraFirma to install it.

UV Resistance: Though there is some UV resistance in the product, it is not meant to sit in the sun all day, every day. Polyaspartic does yellow in the sun over time which is why we recommend it for indoor areas and covered outdoor areas that remain in the shade. There is another UV coating we can put on top that would significantly mitigate yellowing, but that is an additional cost.

Epoxy Floor Options

We have other options for floor finishes, but they are mostly for special cases. Talk to one of our System Design Specialists to learn more.

Decorative Chip Colors

Here’s a selection of what we offer, but these can change. Please check with your System Design Specialist.

Your garage is, well, a garage. It’s fine. Would you rather have a space that looks good, a space you want to use? Yes. That’s why TerraFirma has epoxy floors for you.

What are epoxy floors?

The Simple Answer: It’s a multi-layer system of durable material that is applied to your concrete floor. It also looks good.

The complex answer? Keep reading.

How do epoxy floors work?

Understanding the process of how we install epoxy floors will help you understand how they work. When we get to your home, we:

Prepare the Floor

We start by filling in chips, cracks, and removing anything that would prevent adhesion. This makes it a relatively level surface.

Grind It

We remove the top 1/16” of the concrete by grinding it down. This provides a great surface for our products to adhere to.

The Basecoat

We use a polyaspartic, a two-component, rapid-cure basecoat. It adheres well to the roughed-up concrete.

Broadcast Chips

We literally cast broadly, handfuls of the decorative vinyl chips till we’ve completely covered the floor. We do this while the basecoat is still tacky so the chips will adhere.

Scrape Excess

Then we scrape off the excess decorative flake. Sorry, we didn’t have a pic of this, but this is a nice closeup of the finished product.

Apply Finish

We use a polyaspartic, two-component, rapid-cure floor coating that seals the whole application and dries fast. It’s super durable, stain resistant, has a glossy sheen, and is perfect for indoor or covered spaces.

What do epoxy floors look like?

The main one we install uses vinyl paint chip flakes, and this is what they look like:

They look great. They have the advantage of being able to hide cracks, discoloration, etc. You’d have to look pretty close to see imperfections through floors we install. Even big cracks that we’ve filled can disappear into the random field of chips.

How long do they take to install?

It usually takes one day to install 400 square feet of epoxy flooring. At around 36 hours you can walk on the floor and it’s about four days till you can park your car on it.

Need an Epoxy Floor in your Garage?

Recommended uses for epoxy floors.

There are many places you could install epoxy floors:

- Garages

- Covered Patios

- Home Workshops

- Restaurants, Bars & Cafeterias

- Public Spaces in Stadiums & Malls

- Kennels & Labs

- Lobbies and Restrooms

- Any place you want a hard & tough floor.

Why get TerraFirma’s epoxy floors?

There are a lot of options for floor coatings. Some are cheap DIY projects from Home Depot that will last a year or two, but this isn’t just some paint and chips. TerraFirma provides high quality products & services and epoxy floors are no exception. We install a highly durable system you can feel confident in. Want to know even more? Keep reading below.

Everything about Epoxy Floors

The section above was mostly a summary, so lets get into the nitty-gritty of epoxy floors. We test-installed floors so we could get some good images as well as see the whole process. It’s pretty awesome.

Epoxy Floor Prep

This is a big part of the process and ensures we get good adhesion. Some of the factors are:

- Moisture – Water messes up the basecoat adhesion, so we check to see what moisture sources there are. Luckily, we are masters of water management under your home. TerraFirma can install any of our usual waterproofing/management services if there’s a problem. If that’s not enough we can apply an additional water-proofer under the basecoat for a bit more moisture control. The whole point is we want the basecoat to adhere, and moisture can interfere with that.

- Appliances/Objects – Yeah, you’re going to have to move all that stuff before we start. Things to be aware of:

- Water Heater: Sometimes they’re on a cement platform, but usually they’re on a metal table or sitting on the floor. If you want the epoxy flooring to go underneath, it will have to be moved. We don’t move them.

- Washer & Dryer: The garage is a good place to keep these. If you want the flooring to go under them, you will need to move them. We don’t move appliances.

- Shelving, Tools, etc.: If you want the epoxy flooring in a spot, it needs to be cleared of the things on that spot. We know this seems obvious, but it absolutely needs to be said. Our team is there to apply the flooring only.

- Lifting & Leveling – If the cement is uneven, we can use our Polylevel system to lift it and fill voids underneath the concrete. It’s not going to be perfectly level, concrete is usually pitched so water will run off in a specific direction, but we do want the joints and cracks to be evened out so there are no lips to trip on.

- Cracks – There are two main solutions we have for this:

- Hairline Cracks: We use an epoxy crack filler to fill these in. This is a two-component epoxy that can be used on vertical and horizontal surfaces.

- Large Cracks: We have a polyurea crack-filler that is a highly durable structural repair material and a good long-term fix. We can fill pretty large breaks in concrete with this stuff.

- Seams – When the cement slabs are poured, engineers include expansion gaps and seams. They allow for the slab to expand and handle a small amount of movement without cracking. We like to preserve these joints, so you will see the lines on the finished floor.

- Chips & Holes – That same polyurea crack-filler for large cracks can be used to fill in chips and holes in concrete. We can even use it to replace missing chunks in things like steps. It’s really ugly, but if we’re covering it with an epoxy floor it’ll look great. The best part is you’ll have un-chipped surfaces and straight lines on your steps again.

- Grinding – Once we’ve fixed all the problems with the floor we bring out the big grinder. It tears up the top concrete which provides the best surface for our basecoat. It removes about 1/16 of an inch, but the epoxy floor will more than make up for that. We use big vacuums with centrifuges and filters to make sure we don’t create a huge dust cloud

Epoxy Floor Basecoat

Now that the floor is prepped, we put down the basecoat. It’s a two-component polyaspartic basecoat. We mix the two parts which activate the chemical reactions that will adhere to the concrete as well as the decorative chips later. We cover the entire floor with the basecoat using large metal spatulas. The basecoat is rapid-cure so we don’t have to wait a hours or days before we continue to the next steps. It also has high solids and low odor along with excellent adhesion.

Epoxy Walls?

While we don’t do entire walls of epoxy flooring, we can go up the sidewalls a bit. Often garages will have the foundation stem-wall exposed between the drywall and floor. We can coat this for a nice, finished look. The surface will be rougher than the floor and we include the square footage in the cost.

Epoxy Floor Decorative Chips

This is the star of the show, the part you see. The chips are made from UV stable vinyl which means they are resistant to fading, discoloration, and degradation of the vinyl. It’s good quality stuff and we’re not stingy with it. We throw out enough to cover every inch of floor and then some. It’s about 80 pounds of chips per 400 square feet.

Waste Not

We scrape off the excess decorative flake after the bottom layer has adhered to the basecoat. The surface is not smooth and has some texture to it which will affect the topcoat.

Polyaspartic Coating

The final coating that seals it all is polyaspartic. It’s easy to clean, has a glossy finish, resists abrasion or scratches, has chemical resistance, high solids, low odor, and is LEED compliant. It takes 36 hours before you can walk on it and four before you can park your car on it. The surface, though glossy, will not be smooth because of the decorative chips.

This is where we have to say polyaspartic is not epoxy. Though polyaspartic and epoxy are both resin-based, polyaspartic is not the same thing as epoxy. It’s lumped in with epoxy and other products in the durable floor coating space. And since everyone searches for epoxy floors when looking for polyaspartic, we all call it epoxy.

Polyaspartic cures faster, is a little more UV resistant, and is more durable than epoxy. It’s a better product all the way around. It’s harder to handle and install so that’s why you want a professional like TerraFirma to install it.

UV Resistance: Though there is some UV resistance in the product, it is not meant to sit in the sun all day, every day. Polyaspartic does yellow in the sun over time which is why we recommend it for indoor areas and covered outdoor areas that remain in the shade. There is another UV coating we can put on top that would significantly mitigate yellowing, but that is an additional cost.

Epoxy Floor Options

We have other options for floor finishes, but they are mostly for special cases. Talk to one of our System Design Specialists to learn more.

Decorative Chip Colors

Here’s a selection of what we offer, but these can change. Please check with your System Design Specialist.